Injection Mold Process (Automobiles & Vehicles - Auto Parts & Services)

AUNetAds > Automobiles & Vehicles > Auto Parts & Services

Item ID 2722227 in Category: Automobiles & Vehicles - Auto Parts & Services

Injection Mold Process | |

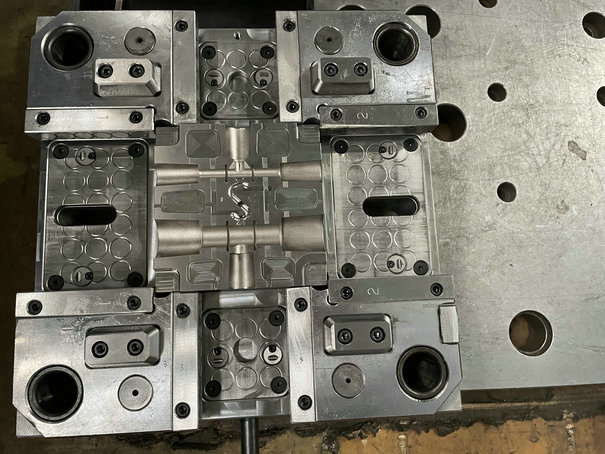

China Plastic Injection Molding Machine-Injection Molding Process Injection molding machines, also known as presses, consist of a material hopper. An injection ram or screw-type plunger, and a heating unit. The molds are clamped to the platen of the molding machine. Where plastic is injected through the sprue orifice to create injection molds. Here we especially introduce a high-speed injection molding machine in China. 1. High-speed injection molding machine Clamping Unit The new generation toggle mold locking device. And computer emulation optimized toggle parameter makes motions of the moving plate fast and steady. 2. High-speed injection molding machine Hydraulic Unit High efficiency, energy-saving, and high precise proportional pressure. And the flow variable displacement pump system makes the hydraulic system output match. The required power for the entire machine operation without high-pressure throttle and overflow energy loss. 3. High-speed injection molding machine Injection Unit The short and forceful double-cylinder injection system is used to ensure steady injection motions. The strain-free fixed mold plate and screw assembly with optimized design help to reach better plasticating capacity and effect. 4. High-speed injection molding machine Control Unit The high-performance special control for injection molding machines. Switch of Chinese and English, clear and visual, and easy operation. Mold making in China Mold is the common term used to describe the tooling used to produce injection molded plastic parts. It is mainly the production of thermoplastic products the most common kind of mold. Plastic injection mold processing equipment for the plastics injection molding machine. Plastic melt is first heated in the heated barrel of the end of the injection machine. And then injection molding machine into the mold cavity under the impetus of a screw or a plunger. The injection machine nozzle and mold casting system. Plastic cooling hardening molding, and mold release to get the products. Its structure is usually molded parts, casting systems, and parts-oriented components. The introduction of institutions, thermostat systems, exhaust systems, and support components.  | |

| Related Link: Click here to visit item owner's website (0 hit) | |

| Target State: All States Target City : All Cities Last Update : 19 August 2025 3:46 PM Number of Views: 16 | Item Owner : injectionmoldchina Contact Email: Contact Phone: 021-52913487 |

| Friendly reminder: Click here to read some tips. | |

AUNetAds > Automobiles & Vehicles > Auto Parts & Services

© 2025 AUNetAds.com

USNetAds.com | GetJob.us | CANetAds.com | UKAdsList.com | INNetAds.com | CNNetAds.com | Hot-Web-Ads.com | USAOnlineClassifieds.com

2025-10-18 (0.466 sec)